Description

The DCMS End Mill is expertly designed for precision machining of hard and brittle materials, such as cemented carbide and ceramics. Featuring a high-adherence diamond coating, this tool ensures extended tool life and consistent performance in demanding applications.

Key Features:

- Coating: Diamond Coating, providing exceptional wear resistance and significantly extending tool life during machining.

- Material: Crafted from Regular Grain Carbide, offering a robust solution for high-precision cutting tasks.

- Cutting Capacity: Suitable for work materials with hardness up to 92.5 HRA.

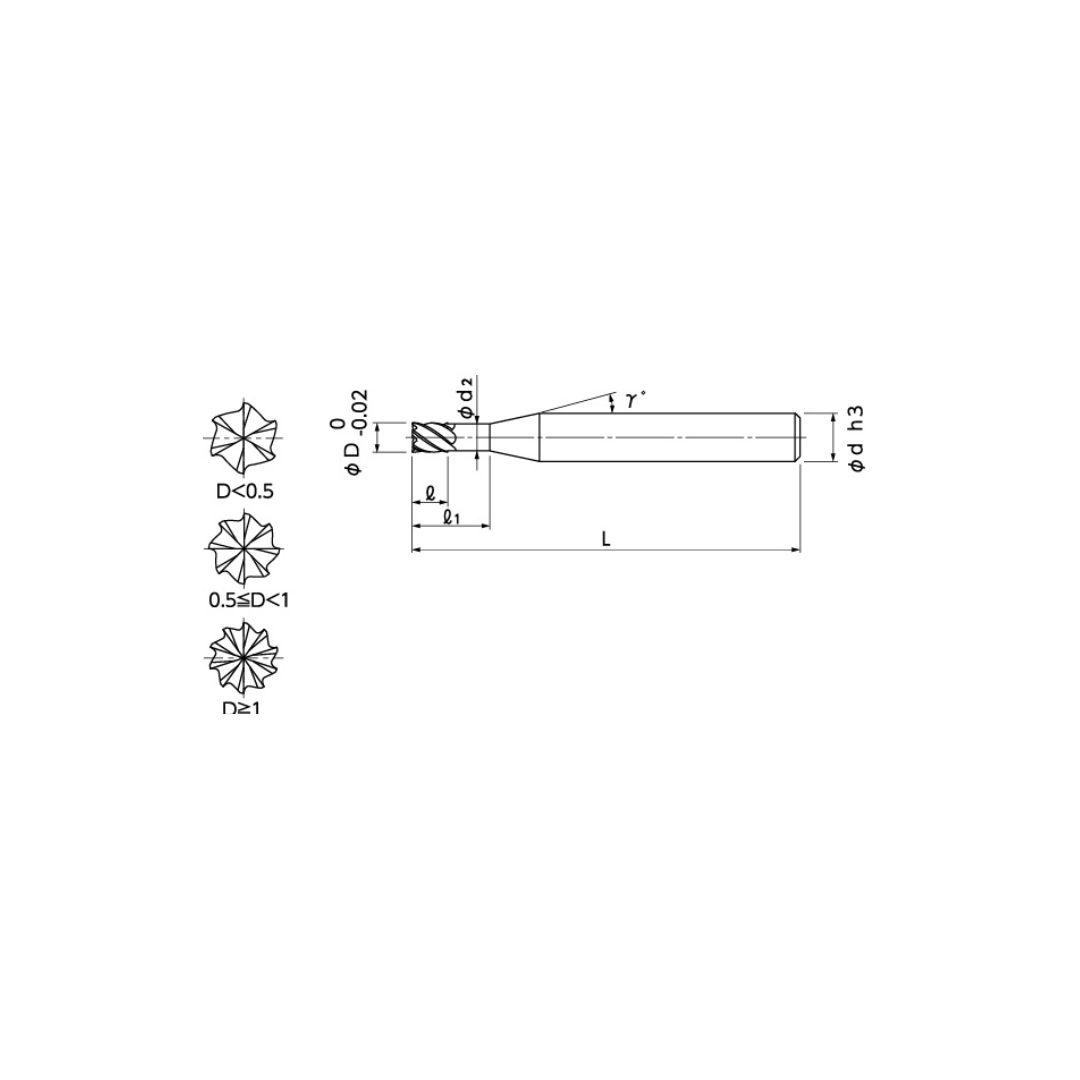

- Number of Flutes: Available in 6, 8, or 10 Flutes, allowing for flexibility depending on the specific machining requirements and desired surface finish.

- Helix Angle: 30°, providing an ideal balance between cutting efficiency and stability.

- Diameter: Available in ⌀d h3, ensuring precise diameter tolerance for accurate machining operations.

- Application: Primarily designed for Face Milling, this end mill delivers excellent results on hard brittle materials, maintaining surface integrity and reducing tool wear.

This end mill is an ideal choice for high-precision machining in industries requiring reliable performance on tough materials. The combination of advanced coating technology and robust design ensures that the DCMS End Mill stands up to the most challenging tasks.

Reviews

There are no reviews yet.