Description

The MMTM M-Thread Mill is engineered for high-precision internal thread milling, leveraging Mugen Coating to extend tool life and enhance cutting performance.

Key Features:

- Coating: Mugen Coating

- Material: Micro Grain Carbide

- Cutting Possibility of Work Material Hardness: Up to 40HRC

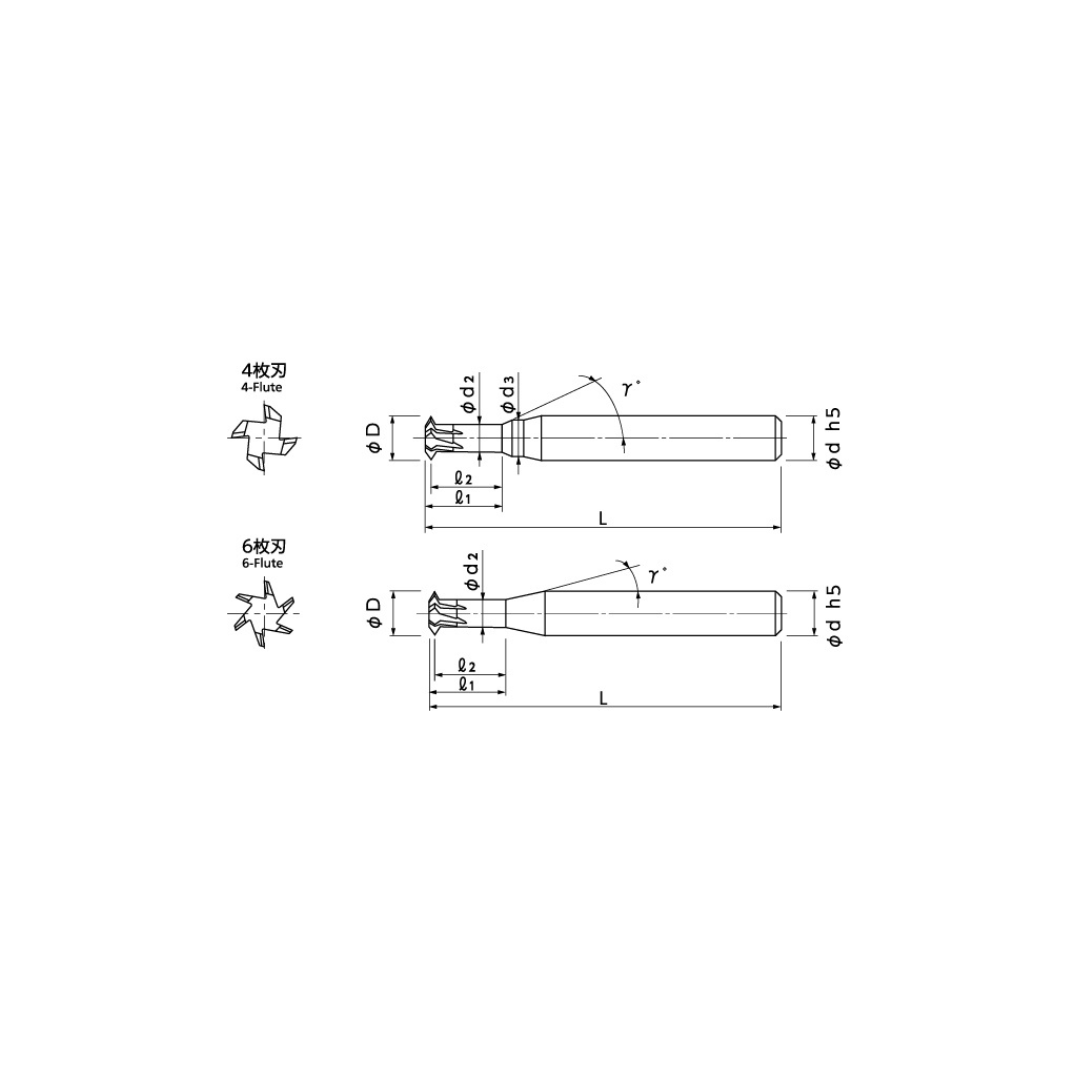

- Number of Flutes: 4 Flutes | 6 Flutes

- Helix Angle: 30°

- Diameter: ⌀d h5

- Application: Thread Milling (Internal)

Special Characteristics:

- Improved Cutting Accuracy: The tool design is optimized for sharpness, which significantly enhances the precision of internal thread cutting.

- Mugen Coating: This coating ensures a longer tool life by reducing wear, especially when working with harder materials.

- Versatile Flute Options: Available in both 4-flute and 6-flute configurations, allowing for tailored performance based on specific threading requirements.

Applications:

The MMTM M-Thread Mill is ideal for industries that demand precise internal threading, such as automotive, aerospace, and precision engineering. Its design and Mugen Coating make it particularly effective in maintaining sharpness and accuracy over extended use, even in harder materials like those up to 40HRC. This tool is well-suited for threading operations where internal thread quality and tool longevity are critical.

Reviews

There are no reviews yet.