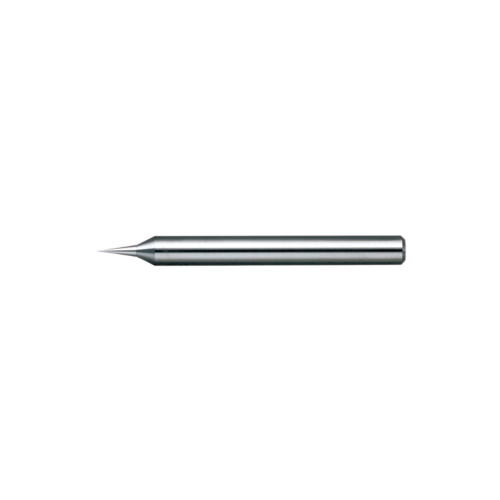

Description

The NSPD-M Micro Point Drill is specially designed for creating precise guide holes, equipped with advanced Mugen Micro Coating for enhanced drilling performance.

Key Features:

- Coating: Mugen Micro Coating

- Material: Super Micro Grain Carbide

- Cutting Possibility of Work Material Hardness: Up to 40HRC

- Number of Flutes: 2 Flutes

- Helix Angle: 30°

- Diameter: ⌀d h3

- Application: Drilling (Guide Hole)

Special Characteristics:

- Guide Hole for Micro Drill: Specifically designed to create guide holes that are essential for accurate drilling operations with Micro Drills.

- Mugen Micro Coating: This special thin film coating enhances drilling performance, particularly in steels, including stainless steels.

- Thinning on the Cutting Edge: Effective from diameters of 0.025mm and above, the thinning reduces cutting forces, enabling more accurate and stable drilling.

Applications:

The NSPD-M is ideal for industries requiring high precision, such as micro-mechanics, electronics, and precision engineering. Its design and coating ensure excellent performance in drilling guide holes, particularly in harder materials like stainless steel, where precision is critical.

Reviews

There are no reviews yet.